Warehousing

HM Group Material Handling have been manufacturing and supplying nestainers for nearly 30 years. We supply many different netainer racks to a variety of industries such as food, manufacturing, logistic and packing, etc.

Nestainer racks are designed to provide a safe and efficient way of managing your factory floor, warehouse or storeroom. Made from mild steel with powder coating finish they ensure that goods can be transported and stored without damage due to the lack-of rough handling while also making it easy for loading in one place then unloading at another location all very quickly!

View our range of nestainer racks below, or contact our team to discuss your requirements to get a customized one.

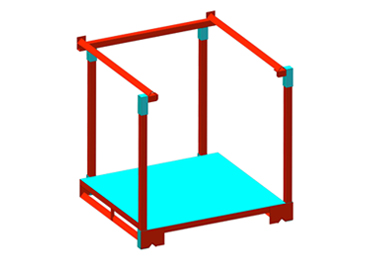

Items are placed at the bottom, you can move the Nestener with a forklift.

For warehouses and sites

Where you do not want to place your items directly on the floor.

That frequently change layouts.

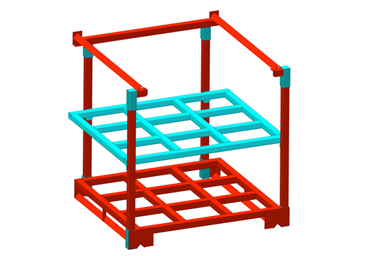

This inverted rack can hold two pallets at once, making it a great space-saving option.

The bottom row can be unloaded by hand lift, making it easy to get to your products.

Perfect storage solution for warehouses and sites with low ceilings.

It is an option that prevents small items and products from collapsing. It can also be installed on the front.

It is an option that suppresses the falling of unstable loads such as flexible container bags. It is also possible to increase the pillar quantity.

It is an option that suppresses the fall of the load. It is possible to increase the number of bars.

It is an option to move the load safely. It can also be installed on the back side.

Two pallets can be stored in one unit, enabling efficient storage.

You can choose the material of the bottom plate from plywood and iron plate. Drilling is also possible.

Freely Movable

Since the nesting rack is not fixed to the floor or walls, so it's very easy to move them around. The layout can be freely adjusted to suit the size of the storage space. It can be used rationally and efficiently.

Increase storage space utilization

The pallet tainers take full advantage of available air space by stacking up to 4 high and around posts, pillars, rafters and ducts. Even non-stackable products, such as bulk bags, roll goods and loose products, can be stacked up to the ceiling.

Save Space

This front-end nesting design allows storage space reduce to about 1/4 of what it used to be. Each pallet tainer adds only 5 1/2 in. to overall nested height and overhang is limited to 2 in. per nesting rack. This results in nesting ratios as great as 12:1, depending on nestainer storage rack's height and depth, and allows rack nesting in low overhead areas.

Earthquake Resistance

The nestainer rack's exclusive inverted angles provide safe, secure and simple stacking. It's designed with a special joining method with different angles of the upper and lower rails (upper rail 90 degrees, lower rail 82 degrees). Due to the cushioning effect generated by the gap created by the different angles, the load on the upper level does not act directly on the lower level. Therefore, the greater the weight applied, the stronger the rails and rails bite into each other, and this design enhances the overall stability.

Nestainer racks function as pallets and containers, providing material transfer as well as storage. This eliminated double handling, reducing your overall material handling costs.

They can then be used as a permanent storage solution, and are particularly popular across the following:

Warehousing

Logistics

Food

Packing and more

Product QC Management

Our strict production process ensures that the company delivers high quality goods to customers. They go through many steps in order for us be able produce top-quality products, from the transportation of raw materials to the processing of the finished products, so you can be confident about what's going into your business!

Container Loading Inspection

We know that shipping containers can be dangerous. That's why our inspectors have to check the structural stability and no signs of damage on these before loading them into a truck or ship, then making sure everything is secure!

1 year Warranty

We offer a 1 year warranty under the condition that your products are used properly and don’t experience any rough handling such as overloading, outdoor exposure to rain for plated products, etc.

Why deal with the hassle of finding a reputable nestainer rack supplier when HM Group has your back? We'll take care everything from manufacturer, clearance and logistics to making sure that you don't have anything else on what's an already busy schedule.

Our team will take the time to understand your needs, offer several solutions and discuss them with you before we move forward. At last, we will discuss the design and confirm a final drawing for production!. The process takes about 3 days from start-to finish but can be shorter or longer depending on how many questions are raised during our meetings together.

Once the final drawing is confirmed, a team of 200+ people who work tirelessly to manufacture your order using advanced equipment. We guarantee strict QC from raw material to finished product for an unmatched experience you'll be satisfied with!.

The whole process usually takes 30 days based on how many items are being made in total - sometimes, however, delivery times are extended for special reasons, such as the revision and confirmation of first sample, or other uncontrollable factors.

Once the products are packed, the trucks will arrive at our factory to pick up your products to the port, then wait for customs clearance. It usually takes about 2 working days to get everything processed!

Your nestainers are on their way! Once they arrive, you'll receive a notification. Shipping time is about 15 to 45 days which varies depending upon where in the world your package is going to be delivered too.

To save you from worries, here are some facts you need to know about a nestainer rack.

We're more than happy to take your custom-sized order! Besides, OEM and ODM are available. However, we have an MOQ request as it's a special one. Please feel free to contact us if you have any questions.

The service life of the Nestener varies depending on the using environment and the weight you load on it. Generally, it can be used for 3 to 5 years under proper uses, but there are many cases where it is used over/less than this period.

It takes up to 4 weeks to deliver your order with no order customization but may take longer with customization. This is because we ensure that every customized rack you order is uniform and high quality.

Unfortunately, sometimes things go wrong even though we ensure top-notch safety. When this happens we're here to help! You can contact our customer support team and they'll provide you the assistance that's needed.

We have a detailed delivery schedule. We'll keep you updated about any potential delays or complications. In case of any force majeure, such as the COVID-19 pandemic, please expect minimal delays in order processing and delivery.

In order to supply the nestainer rack that best fits your specific application, the following information is needed.

We build the solutions that make businesses run smoother than ever. So let us help you with whatever your needs may be!

8:00 am - 6:00 pm